We deliver SICK “Sensor Intelligence”

Sick sensor solutions for Industrial automation are the result of exceptional dedication and experience. From development all the way to service.

The people at SICK are committed to investing all their expertise in providing with the very best sensors and system solutions possible.

Versatile product range for industrial automation:

This extensive range of photoelectric sensors is used in many automation applications around the world.

- Fiber-optic sensors and fibers

- Cylindrical photoelectric sensors

- MultiTask photoelectric sensors

- Miniature photoelectric sensors

- Small photoelectric sensors

- Compact photoelectric sensors

- Inductive proximity sensors

- Capacitive proximity sensors

- Magnetic proximity sensors

- Analog positioning sensors

- Sensors for T-slot cylinders

- Sensors for C-slot cylinders

- Sensor adapters for other cylinder types

The variety of tasks in automated production processes today, such as in packaging and printing machines, require sensors with the highest performance standards. Typical applications are the detection of visible and non-visible marks, labels and colors at high speeds as well as the detection of small parts and precise positioning. SICK offers a wide range of contrast, markless, color, luminescence, fork and array sensors to solve this wide spectrum of demanding tasks.

- Contrast sensors

- Markless sensors

- Color sensors

- Luminescence sensors

- Gas flow meters

- Measuring automation light grids

- Switching automation light grids

- Safety laser scanners

- Safety light curtains

- Safety camera systems

- Multiple light beam safety devices

- Single-beam photoelectric safety switches

- Mirror columns and device columns

- Upgrade kits for opto-electronic protective devices

In conjunction with safe control solutions, SICK offers ideal complete solutions from a single source.

- Electro-mechanical safety switches

- Non-contact safety switches

- Safety locking devices

- Safety command devices

- Safe sensor cascade

- Safety controllers

- Motion Control safety controllers

- Safety relays

- Gas transmitters

- In-situ gas analyzers

- Extractive gas analyzers

SICK is setting new standards in dust measurement with its rugged and low-maintenance measuring devices for detecting and monitoring dust concentrations. All dust measuring devices are easy to integrate into existing applications – and offer straightforward installation and commissioning along with user-friendly operation.

SICK is setting new standards in dust measurement with its rugged and low-maintenance measuring devices for detecting and monitoring dust concentrations. All dust measuring devices are easy to integrate into existing applications – and offer straightforward installation and commissioning along with user-friendly operation.- Scattered light dust measuring devices

- Transmittance dust measuring devices

- Gravimetric dust measuring devicesrs

- CEMS solutions

- Process solutions

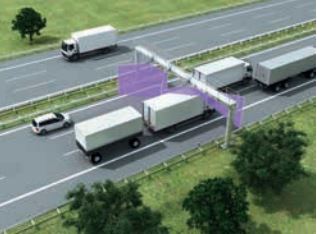

- Tunnel sensors

- Overheight detectors

- Visual range measuring devices

- Volume flow measuring devices

- Mass flow measuring devices

- Flow velocity measuring devices

- Gas flow meters

- Image-based code readers

- Bar code scanners

- RFID

- Hand-held scanners

- Connectivity

- Image-based code readers

- Bar code scanners

- RFID

- Hand-held scanners

- Connectivity

- Displacement measurement sensors

- Mid range distance sensors

- Long range distance sensors

- Linear measurement sensors

- Ultrasonic sensors

- Optical data transmission

- Position finders

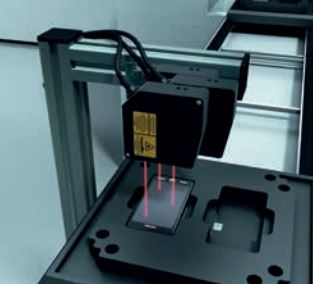

- 2D laser scanners

- 3D laser scanners

- Radar sensors

- Motor feedback system rotary HIPERFACE®

- Motor feedback system rotary HIPERFACE DSL®

- Motor feedback system rotary incremental

- Motor feedback system rotativ incremental with commutation

- Motor feedback system linear HIPERFACE®

The range is capped off by inclination sensors that enable non-contact detection of angles in one or two axes.

- Absolute encoders

- Incremental encoders

- Linear encoders

- Wire draw encoders

- Safety encoders

- Inclination sensors

- Measuring wheel encoders

- Level sensors

- Pressure sensors

- Flow sensors

- Temperature sensors

The high quality of our components and the dedication and expertise of our employees validate the core concept behind SICK: outstanding solutions for demanding tasks.

- Customized analyzer systems

- Driver assistance systems

- Robot guidance systems

- Object detection systems

- Quality control systems

- Security systems

- Track and trace systems

- Functional safety systems

- SICK AppSpace

- Analytics Solutions

- Integrated Managing Solutions